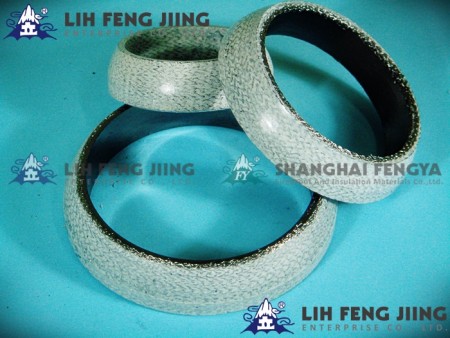

Exhaust Joint Seal Rings

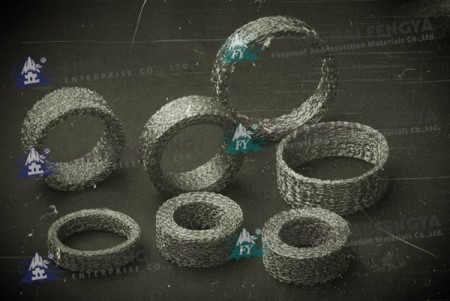

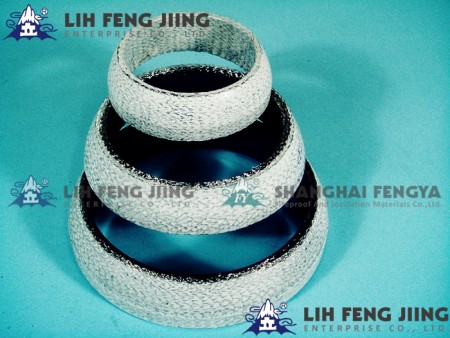

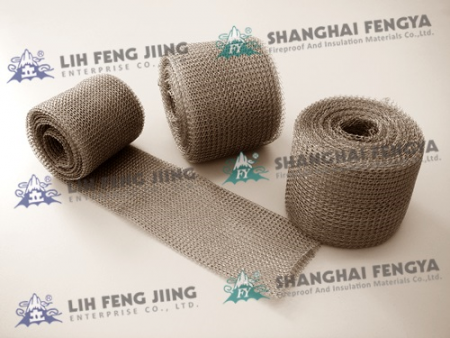

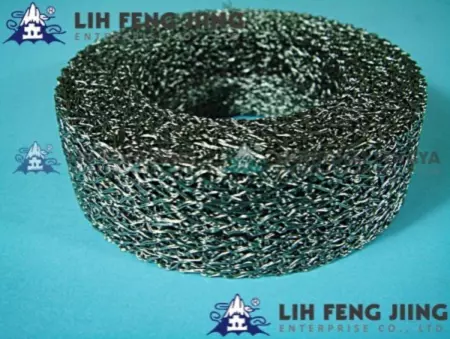

Exhaust joint seal rings are made of special compressed knitted wire mesh, and they can be coated with mica, Teflon, and graphite for different properties.

Product Description

Exhaust joint seal rings are mainly used for joint connection in flexible intermediated elements from the exhaust manifold to the muffler, where temperature and leakage requirements are stringent.

Features

- Resilience and durability

- High temperature duration

- Noise and squeak minimizing

- Low friction and sealing enhance

Type

- Mild steel knitted mesh with mica or graphite -----600℃ ~ 750℃.

- Stainless steel knitted mesh with mica or graphite------700℃ ~ 900℃.

Specification

- Made to specification as per drawings from customer

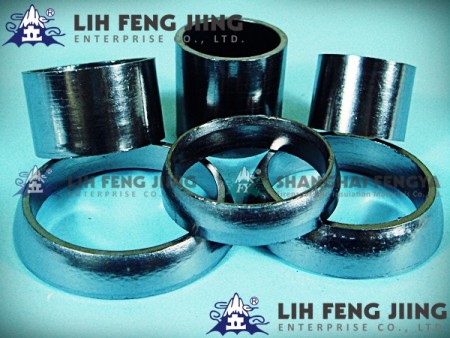

Application

- Manifold gaskets

- Exhaust system connections

- Static joints

- Exhaust rigid pipe connections

- <br>

- Application Gallery

- Related Products

Knitted Wire Mesh (Connected Wire Mesh)

Knitted wire mesh is produced as a mesh structure of asymmetric interlocking loops in different...

DetailsEngine Breathers

Engine breather is made of knitted wire mesh, choose high quality galvanized steel wire or stainless...

DetailsSpacer Mesh Ring

Spacer mesh ring is made of knitted wire mesh, compressed to become different shapes, diameters...

DetailsCatalytic Converter Support Mesh and Seals

Catalytic converter support mesh and seals are made of different grades of high nickel content...

DetailsExhaust Decoupling Rings

Exhaust decoupling rings are made of knitted wire mesh, shaped as cylindrical configuration...

DetailsKnitted Wire Mesh Filters

Knitted wire mesh filters are made of knitted wire mesh being compressed. The compressed knitted...

Details- Files Download

Tags

- Woven Metal Materials

- Forms of Knitted Mesh

- Knitted wire mesh filter element

- Knitted wire mesh exhaust gasket

- Knitted wire mesh EMI shielding gasket

- Knitted wire mesh insulating blanket

- knitted wire mesh gasket

- knitted wire mesh tube

- knitted wire mesh tape

- knitted wire mesh muffler

- knitted wire mesh insulation

- Ring seal

- Knitted wire mesh seals

- Knitted wire mesh exhaust seals

- Wire mesh seal ring

- Wire mesh seals

- Wire mesh seal ring

- Wire mesh gasket

- Airbag Filters

- Spacer rings and air gap seals

- Separation Rings

- Catalytic Converter Mesh Wraps

- Anti-Vibration

- Sound Attenuation And Heat Shields

- Engine Breathers

- Exhaust decoupling rings and mesh bellows sleeves

- Silencer and muffler packing

Exhaust Joint Seal Rings | Lightweight PP+GF Composite Sheet/Felt, Stainless Steel/Wool/Felt, Bulked Fiberglass Roving for fireproof industry | Lih Feng Jiing Enterprise Co., Ltd.

Located in Taiwan, China since 1975, LFJ has been a stainless steel thermal and acoustic insulation products manufacturer that is specialized in the production of Exhaust Joint Seal Rings, High-Temperature Fiberglass Needle Mat, Lightweight PP+GF Composite Sheet/Felt, Stainless Steel/Wool/Felt, Bulked Fiberglass Roving used for the fireproof material industry.

ISO9001-2000 and IATF 16949 certified, LFJ's refined high-temperature resistance and sounds absorption product is certified to meet international standards. Along with high-temp fiberglass needle mat,, there are stainless steel wool, e-glass and PP, knitted wire mesh, glass roving, etc. Especially in autos and motorcycles, our Fiberglass Needle Mat and Stainless Steel Wool are always in the lead, not only in quality, price or technical service, we pursuing customers' satisfactory, and get the recognition and support from our customers.

LFJ has been providing high-quality products, both with advanced technology and 47 years of experience, LFJ ensures each customer's demands are met..

.png?v=55224b43)