Ceramic Fiber Products 1260~1800℃

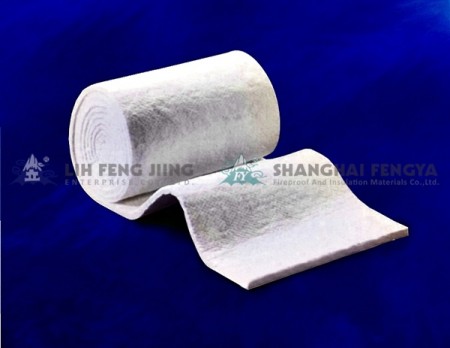

Ceramic fiber made of various thermal insulation products

HIWOOL ceramic fiber has excellent resistance to high temperature and heat insulation, in different areas is available to provide different types of products to users a wide range of options.

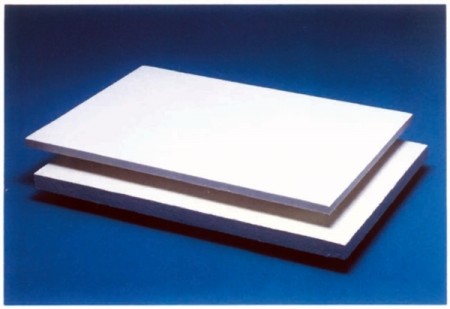

For the special needs of customers, the development does not contain any organic molding agent of the ceramic fiberboard, during the heating process will not produce bad smell and the board won't release smoke or turn to black.

Features

- Excellent heat insulation

- Good sound absorption;

- Excellent tensile strength;

- Good thermal stability;

- Good thermal shock resistance;

- Well High temperature chemical stability

- High temperature small shrinkage ;

- Good resilience;

- Low heat capacity.

Specification

| TYPE | SPECIFICATION | |||||

| Temperature | Density | Thickness | Width | Length | ||

| ℃ | KG/M3 | mm | mm | M | ||

| Ceramic wool 1260℃~1600℃ 64K~160KG/M3 6, 10, 13, 25, 50mmT | 1260 1430 | 96 128 | 13 25 50 | 600 | 14.4 7.2 3.6 | |

| Ceramic wool brick 1260℃~1600℃ 160K~240KG/M3 200, 250, 300, 600mmT | 1260 1430 | 160 | 300 | 300 | 150 300 350 | |

| Ceramic board 1260℃~1800℃ 250K~400KG/M3 6, 10, 13, 25, 50mmT | 1260 1430 | 280 | 25 50 | 600 1200 | 900 1000 | |

| Ceramic loose wool 1260℃~1600℃ | 1260 1430 | - | - | - | - | |

| Ceramic paper 1260℃, 1430℃ 180K~220KG/M3 1~6mmT | 1260 | 200 | 2 3 5 | 610 1220 | 60 30 20 15 12 10 | |

| Ceramic Vacuum Form 1260℃~1600℃ | - | 280 | According to customer's requirements | |||

| Ceramic wool tube 1260℃~1600℃ | According to customer's requirements | |||||

Application

- Fire door insulation

- Furnace furnace wall gap filling;

- Household appliances insulation;

- Industrial equipment sealed insulation;

- Boiler, cracking furnace, annealing furnace, glass furnace and high temperature pipe insulation.

- <em><span style="text-decoration: underline;"><strong>Iron and steel plant insulation</strong></span></em></p>

- <em><span style="text-decoration: underline;"><strong><img src="/Templates/pic/TN001.steel_iron_factory%20(10).jpg" width="340" height="255" alt="steel_iron_factory " /><img src="/Templates/pic/TN001.steel_iron_factory%20(7).JPG" width="340" height="255" alt="1" /></strong></span></em></p>

- <img src="/Templates/pic/ceramic-products-app.JPG" width="818" height="395" alt="ceramic" /></p>

- Application Gallery

- Files Download

Ceramic Fiber Products 1260~1800℃ | Lightweight PP+GF Composite Sheet/Felt, Stainless Steel/Wool/Felt, Bulked Fiberglass Roving for fireproof industry | Lih Feng Jiing Enterprise Co., Ltd.

Located in Taiwan, China since 1975, LFJ has been a stainless steel thermal and acoustic insulation products manufacturer that is specialized in the production of Ceramic Fiber Products 1260~1800℃, High-Temperature Fiberglass Needle Mat, Lightweight PP+GF Composite Sheet/Felt, Stainless Steel/Wool/Felt, Bulked Fiberglass Roving used for the fireproof material industry.

ISO9001-2000 and IATF 16949 certified, LFJ's refined high-temperature resistance and sounds absorption product is certified to meet international standards. Along with high-temp fiberglass needle mat,, there are stainless steel wool, e-glass and PP, knitted wire mesh, glass roving, etc. Especially in autos and motorcycles, our Fiberglass Needle Mat and Stainless Steel Wool are always in the lead, not only in quality, price or technical service, we pursuing customers' satisfactory, and get the recognition and support from our customers.

LFJ has been providing high-quality products, both with advanced technology and 47 years of experience, LFJ ensures each customer's demands are met..

.JPG?v=409af2ab)

.JPG?v=53d8e52e)