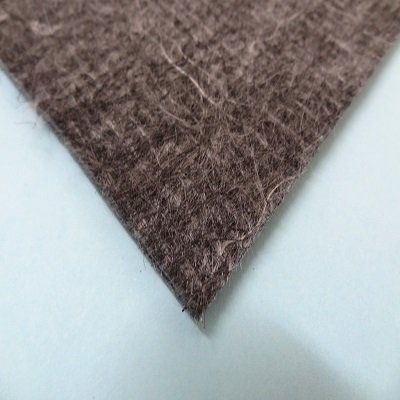

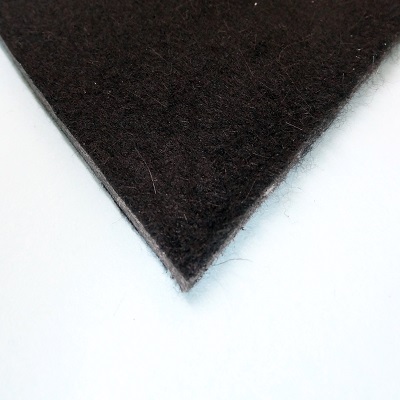

LWGMT For Car Side Cover

The lightweight composite products are manufactured by using PP(polypropylene) along with glassfilber through needle punching process into Mat/Felt, and process it into sheets by heat pressing.

Designed glassfiber with PP, which offering its weight reducing but with high strength properties.

The needled rolls and sheets can be laminated with multiple combinations such as PE films , Fabrics or other composites without any self-adhesives, combination elements can be completed at production step which will make more cost-effective.

The sheets can be cut-to-size for easy operation and lower transportation cost, any complicated shape or form can be molded by low pressure moulding in 3D mould.

LFJ's lightweight products is produced by special processing which is an excellet noise absorbent, as a sheet, LWGMT can be utilized in replacement of PU foam, traditional GMT, timber, polywood, fiberboard, polymer rigid foams and so on. Molded into 3D mould at low pressure re-heating processes, the LWGMT can be return to 1.5 to 5 times basis orginal thickness of boards. Various thickness with components are available according to customers' requirements.

Features

- Weight reducing

- Higher strength

- Lower VOC.

- Good insulations and acoustic absorptions

- Varies complex shape or form can be molded by multiple times

- Production cost down

- Solidity forming dimensions

- Chemicals resistance

- High durability

- Recycle products, good for environment protection

- Convenient on loading, lower shipment cost

Specification

| Type | Specification | |||||

| Area Weight | Thickness | Width | Length | |||

| g/m² | mm | Meter | Meter | |||

| LWGMT Mat | 700~2600 | 3~25 | 0.3~3.3 | 10~50 | ||

| LWGMT Sheet | 700~2600 | 1.8~10 | 0.5~2.1 | Max. 3.3 | ||

| ※ Specified dimensions can be customized , welcome to give us an inquiry. | ||||||

- Related Products

LWGMT For Car Headlines

The lightweight composite products are manufactured by using PP(polypropylene) along with glassfilber...

DetailsLWGMT For Engine Under Cover

The lightweight composite products are manufactured by using PP(polypropylene) along with glassfilber...

DetailsLWGMT For Car Shelf

The lightweight composite products are manufactured by using PP(polypropylene) along with glassfilber...

Details- Files Download

Tags

- E-glass

- PP mat

- Lightweight sheet

- polypropylene

- Glass Fiber

- headlining

- Headliner (performances)

- Glass Fiber-PP Composite base material hardboard

- Glass fiber reinforced hardboard

- Fiberglass reinforced thermoplastic panels

- Glass fiber reinforced thermoplastic material

- Rear parcel shelf

- Sun visor

- Splash shield

- Interior sand storage panels

- Luggage compartment

- Bulding roof

- Bulding floor

- Bulding interior

LWGMT For Car Side Cover | Lightweight PP+GF Composite Sheet/Felt, Stainless Steel/Wool/Felt, Bulked Fiberglass Roving for fireproof industry | Lih Feng Jiing Enterprise Co., Ltd.

Located in Taiwan, China since 1975, LFJ has been a stainless steel thermal and acoustic insulation products manufacturer that is specialized in the production of LWGMT For Car Side Cover, High-Temperature Fiberglass Needle Mat, Lightweight PP+GF Composite Sheet/Felt, Stainless Steel/Wool/Felt, Bulked Fiberglass Roving used for the fireproof material industry.

ISO9001-2000 and IATF 16949 certified, LFJ's refined high-temperature resistance and sounds absorption product is certified to meet international standards. Along with high-temp fiberglass needle mat,, there are stainless steel wool, e-glass and PP, knitted wire mesh, glass roving, etc. Especially in autos and motorcycles, our Fiberglass Needle Mat and Stainless Steel Wool are always in the lead, not only in quality, price or technical service, we pursuing customers' satisfactory, and get the recognition and support from our customers.

LFJ has been providing high-quality products, both with advanced technology and 47 years of experience, LFJ ensures each customer's demands are met..